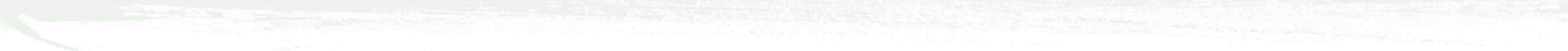

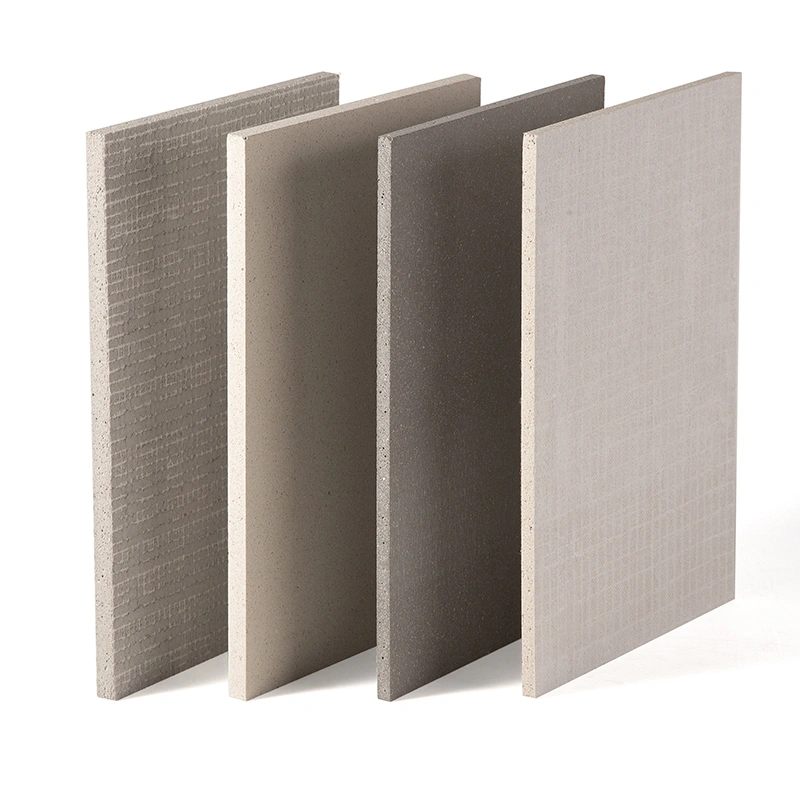

Ceramic Fibre Board offers excellent thermal and physical stability, cold handling strength and corrosion resistance whilst also being lightweight, resilient and able to be utilised in direct contact with flame.If the board does become wet by water of steam, thermal and physical properties are restored upon drying.

As a result of this unique combination of characteristics, Ceramic Fibre Boards are often used in applications ranging from duct insulation, expansion joints, flue and chimney linings, furnace, kiln and boiler face as well as back up insulation for hard refractory.

Specifiacation

| Тип |

Common |

Standard |

High Pure |

High alumina |

Zirconium |

| Classification temperature (°С) |

1100 |

1260 |

1260 |

1360 |

1430 |

| Working temperature (°С) |

≤1000 |

1050 |

1100 |

1200 |

1350 |

| Цвет |

Белый |

Pure White |

Pure White |

Pure White |

Pure White |

| Плотность (kg/m3) |

260

320 |

260

32 |

260

320 |

260

320 |

260

320 |

| Shrinkage on heating (%)(Temperature 24 часы, density as 320kg/m3) |

-4

(1000°С) |

-3

(1000°С) |

-3

(1100°С) |

-3

(1200°С) |

-3

(1350°С) |

| Thermal conductivity of various temperatures (w/m.k) (density 285kg/m3) |

0.085

(400°С)

0.132

(800°С)

0.180

(1000°С) |

0.085

(400°С)

0.132

(800°С)

0.180

(1000°С) |

0.085

(400°С)

0.132

(800°С)

0.180

(1000°С) |

0.085

(400°С)

0.132

(800°С)

0.180

(1000°С) |

0.085

(400°С)

0.132

(800°С)

0.180

(1000°С) |

| Прочность на сжатие (МПа) |

0.5 |

0.5 |

0.5 |

0.5 |

0.5 |

Chemical composition

(%) |

AL2O3 |

44 |

46 |

47-49 |

52-55 |

39-40 |

|

AL2O3+SIO2 |

96 |

97 |

99 |

99 |

- |

|

AL2O3+SIO2+ZrO2 |

- |

- |

- |

- |

99 |

Low thermal conductivity and ow heat storage

High temperature stability and resistant to thermal shock

High crushing strength and good toughness

Allow machining and cutting, easy application

Resistant to airflow erosion

Strong pressive strength

Good erosion resistance

Shorter heat up and cool down time

Non-brittle material, good elasticity

Heat capacity and low thermal conductivity

Excellent chemical stability and thermal stablity

Good thermal shock resistance

High compressive strength

Heat resistance for fireplace

Typical Application

all kinds of industrial furnace hot face and back face insulation;

kiln line of the high-temperature furnace, kiln cars, door damper, furnace temperature to separate plate;

deep processing products molding mould, like Craft glass etc;

astronautical,Shipbuilding heat insulation,fireproofing, sound proofing, изоляция;

heat insulation for back lining of high temperature industrial furnace;

hot surface of industrial furnace ,electric furnace porcelain furnace, heat treatment furnace, mechanical and metallurgical furnace;

combustion chamber construction;

ceramic industry (kiln lining, kiln car insulation );

glass industry(glass tank wall, side, end wall and port neck insulation);

heat resistance for fireplace;

heat insulation of high temperature and high heat equipment.