1. Spun Aluminum Silicate Needle Punched Blankets

Our company has an annual production capacity of 35,000 tons, filling a gap in Shandong Province. Spun blankets utilize a resistance furnace process, undergoing high-temperature melting, spinning, and solidification. This process significantly improves fiber length, fineness, tensile strength, and delamination resistance. They offer advantages such as lightweight, ball-free construction, и простота установки. Spun blankets contain no organic matter, ensuring excellent reliability and stability at high temperatures. Due to their excellent thermal insulation properties, spun blankets are widely used in large-scale national engineering projects and exported to countries such as Malaysia and Iraq.

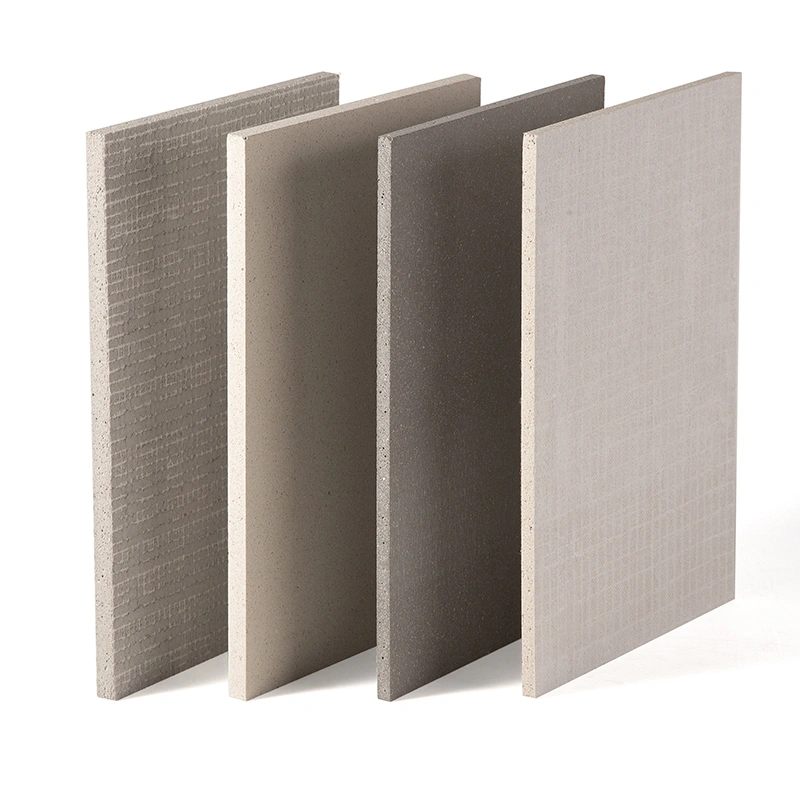

2. Blown Aluminum Silicate Needle Punched Blankets

Blown blankets utilize a resistance furnace process, undergoing high-temperature melting and secondary blowing. Depending on the raw materials used, they can be categorized as standard, high-purity, high-aluminum, and zirconium-containing types.

Technical index

| Product Code |

HTTX-PT-01 |

HTTX-BZ-01 |

HTTX-GC-01 |

HTTX-GL-01 |

HTTX-DG-01 |

HTTX-HG-01 |

| Classification Temperature(℃) |

1050 |

1260 |

1260 |

1350 |

1350 |

1430 |

| Диаметр волокна(мкм) |

3~5(Spinning) |

3~5(Spinning) |

3~5(Spinning) |

2~4(Blowing) |

3~5(Blowing) |

3~5(Blowing) |

| 2~4(Blowing) |

| Slag Ball Content(Φ≥0.212mm)(%) |

≤20 |

≤20 |

≤15 |

≤15 |

≤15 |

≤15 |

| Chemical Composition(%) |

Al₂O₃ |

≥40 |

≥43 |

≥44 |

≥52 |

- |

- |

| Al₂O₃+SiO₂ |

≥95 |

≥97 |

≥98.5 |

≥98.5 |

- |

- |

| Al₂O₃+SiO₂+ZrO₂ |

- |

- |

- |

- |

- |

- |

| ZrO₂ |

- |

- |

- |

- |

- |

|

Note: The above values are average values measured according to test standards and will fluctuate within a certain range, not guaranteed values.

For more information on this product, please contact the Technical Engineering Department of Ping Haotai Energy Saving Materials Co., ООО.