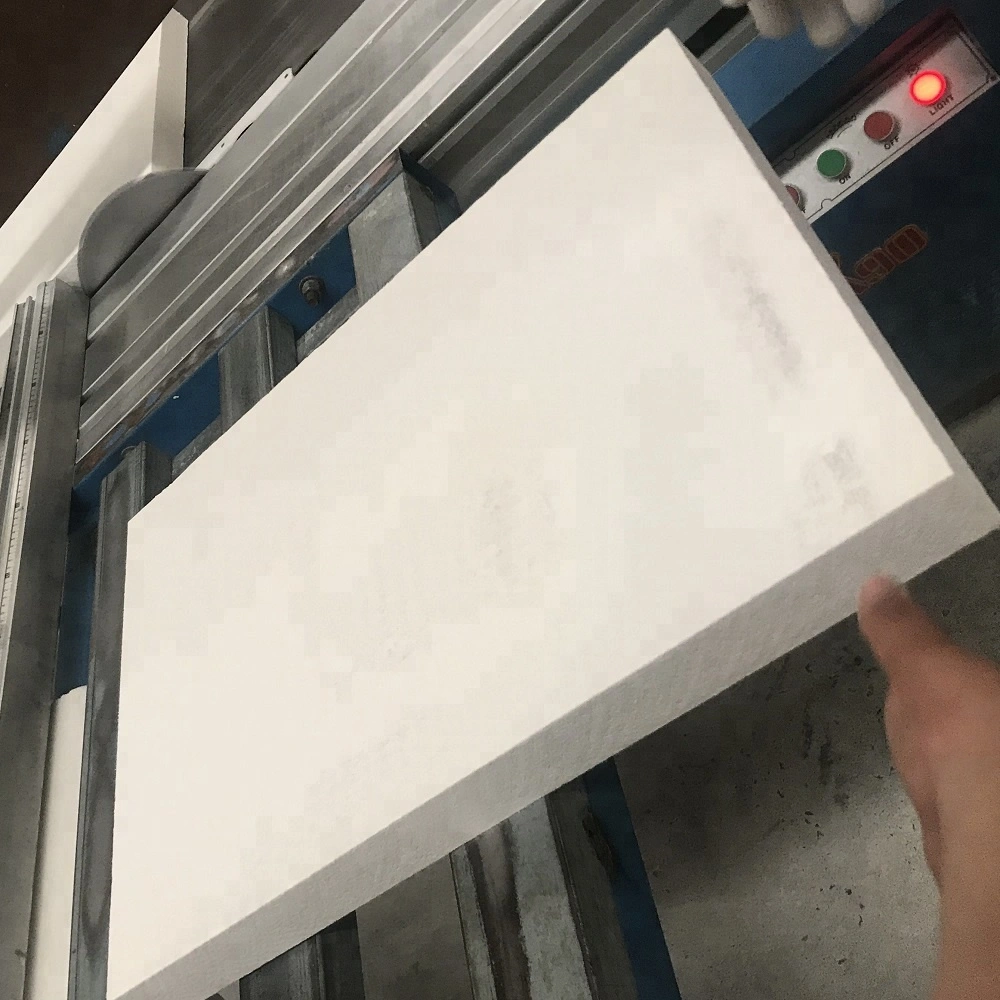

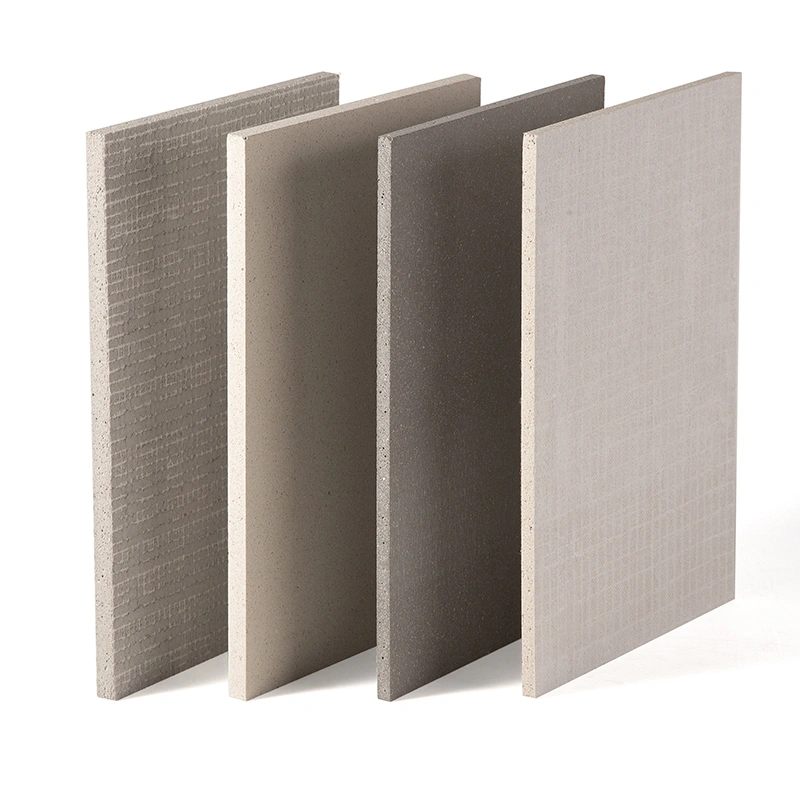

This rigid board product is made from loose ceramic fibers mixed with appropriate organic and inorganic binders, vacuum-formed, dried, and then finely processed. It is widely used for refractory insulation of various furnace interiors and exterior walls, as well as for insulation in areas subject to high-temperature airflow.

Aplicativos

1. Industrial furnaces

2. Construction projects, fireproofing and insulation for fire doors

3. Power industry, gas turbines, and furnace door and roof seals

4. Thermal insulation in the power, petroleum, cimento, and aluminum industries

Technical index

| Tipo |

Standard Fiberboard |

High-Purity Fiberboard |

High-Aluminum Fiberboard |

Zirconium-Containing Fiberboard |

Chromium-Containing Fiberboard |

Polycrystalline Fiberboard |

Soluble Fiberboard |

| Classification Temperature℃ |

1260 |

1260 |

1300 |

1430 |

1500 |

1600 |

1100 |

| Bulk Density(kg/㎥) |

300±10% |

400-600 |

300±10% |

| Slag Ball Content(75μm) |

≤50% |

- |

- |

| Hardness(Shore C) |

≥60 |

≥55 |

≥60 |

| Flexural Hardness(Mpa) |

≥0.8 |

- |

≥0.8 |

| Compressive Strength(Mpa) |

≥1.0(Thickness Compression10%) |

- |

≥1.0 |

| 24-Hour Thermal Insulation With Permanent Linear Shrinkage |

≤3.0(1000℃) |

≤3.0(1100℃) |

≤3.0 (1200℃) |

≤3.0 (1350℃) |

≤2.0 (1400℃) |

≤1.0(1500℃) |

≤2.0 (1000℃) |

| Loss On Ignition(%) |

≤8 |

| Condutividade Térmica (W/m.K) (average temperature) |

0.08(400℃) |

| 0.11(600℃) |

| 0.15(800℃) |

| 0.19( 1000℃) |

| Especificações do produto |

Length*Width*Thickness(mm) |

| 1200*1000*10-100 1200*500*10-100 1000*600*10-100 |

| Length and width deviation ±2mm Thickness deviation -1, +2milímetros |