Why has sanding board been widely used in the construction industry in recent years? What are the characteristics of this emerging building material? Next, we will explain it to you:

Glass magnesium sanded board has good fireproof performance and is a non-combustible board. The flame continues to burn for zero time, does not burn at 800℃, and has no flames at 1200℃, reaching the highest fireproof and non-combustible level A1. The partition system made of high-quality keels has a fire resistance limit of more than 3 hours. It can absorb a large amount of heat energy during the combustion process and delay the increase in the surrounding temperature.

Waterproof and Moisture-Resistant:

Sanded boards maintain consistent performance in both dry, cold, and humid weather, unaffected by condensation and humidity. Even after being soaked in water for several days and then allowed to air dry, they remain stable and can be used normally without any moisture absorption or reversion. Testing has shown that the boards are impermeable.

Lightweight and earthquake-resistant:

Glass magnesium fireproof sanded board has an apparent density of 0.8-1.2g/cm³, reducing building loads and reducing the weight of interior walls by over 60%, while also increasing usable floor space by 5-8%. Its light weight contributes to structural earthquake resistance, effectively reducing the cost of foundations and main structures.

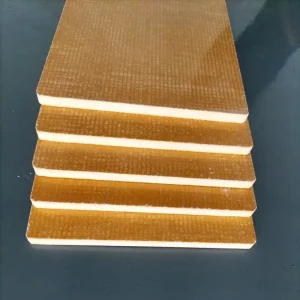

Superior Strength:

Magnesium's unique 5.1.8-phase densely packed glass fiber cloth and highly resilient plant fibers make this board lightweight yet compact, stable, and deformation-resistant. It possesses wood-like toughness and demonstrates excellent impact, compression, tension, and fracture resistance. Its balance of strength and toughness achieves flexural strengths of 322 kgf/cm² (vertical) and 216 kgf/cm² (horizontal), and an impact strength of 25 MPa.

Environmentally friendly and healthy:

Glass-magnesium sanded fireproof board contains absolutely no asbestos, formaldehyde, benzene, or harmful radioactive elements. It is smokeless, non-toxic, and odorless when exposed to fire. Made from natural mineral powder and plant fibers, the production process is naturally curing, requiring little energy and producing no waste. It is energy-efficient and environmentally friendly, and the board surface does not shed dust during use. Its unique natural pore structure regulates indoor temperature, making living and office spaces more comfortable.

Thermal Insulation and Energy Saving:

Glass magnesium fireproof sanded board features uniform fine pores, a dense structure, and inorganic properties. Its thermal conductivity is 0.216 W/cm·K, significantly higher than the 1.1 W/cm·K of lime sand masonry blocks. This reduces energy consumption and maintains a comfortable, fresh air environment in your home.

Affordable:

Sanded board offers stable and reliable quality, a high cost-effectiveness, and is lightweight, high-performance, and reasonably priced. It offers excellent processing and installation performance and can be attached, cut, nailed, drilled, painted, and planed. It's easy to carry and features excellent toughness and resistance to breakage. It can be easily installed using self-tapping screws, nail guns, and straight nails, and can be installed using both wet and dry methods.

Soundproofing and Tranquility:

The sanded board's superior sound insulation ensures a tranquil and elegant living environment. The board's light weight and thinness do not affect the sound insulation performance of the glass magnesium fireproof board. A 6mm thick board reduces sound waves by 29dB. A partition system consisting of double-sided, single-layer 9mm glass magnesium fireproof board, 75mm keel, and 50mm rock wool achieves airborne sound insulation exceeding 42dB. Its unique, uniform pore structure is unmatched by other denser glass magnesium fireproof boards.

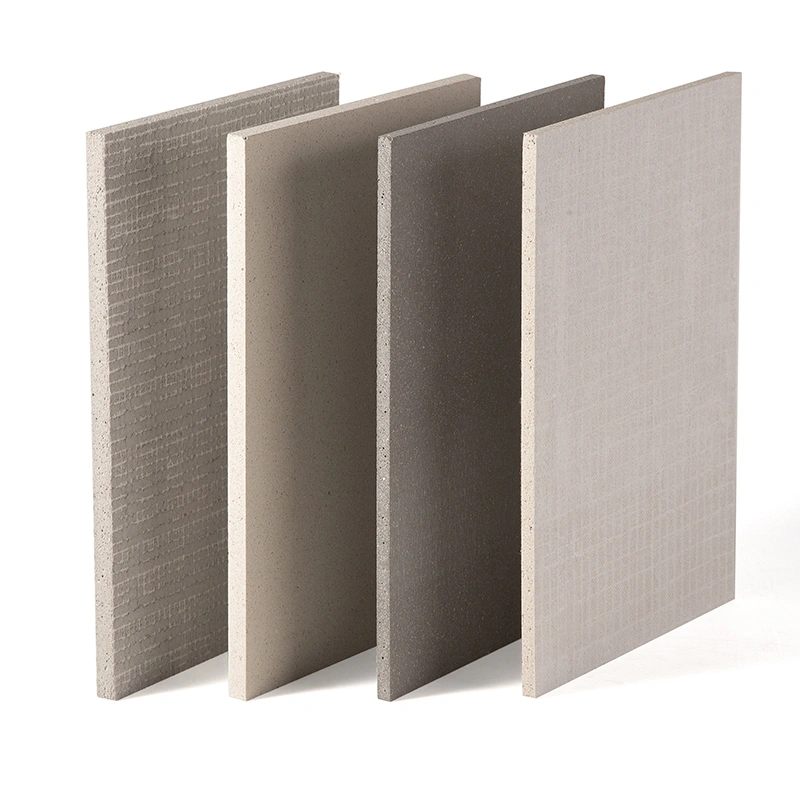

Versatility:

Glass magnesium fireproof sanded board's unique smooth and rough surfaces offer a wide range of applications. The smooth surface can be used for wallpaper, aluminum-plastic panels, fireproof panels, veneer, PVC, and can be sprayed with paint or latex paint. The rough surface can be used for tiles, marble, granite, plaster, and latex paint. Glass magnesium fireproof board has excellent compatibility with these materials and can be reprocessed and reused on-site. It can be bent into shapes up to 30 cm in diameter without sacrificing physical properties.

Durability:

The scientific formula completely eliminates the moisture absorption and halogen regeneration issues of magnesia. Its strength increases over time, and it resists corrosion, acids, and alkalis. Thermal expansion and contraction are minimal, with a drying shrinkage rate of ≤0.3% and a wet expansion rate of ≤0.6%. It is also frost-resistant to -40°C. After a decade of testing, glass magnesium fireproof board is durable, resistant to aging, and has a long lifespan.

Insect and Mildew Resistant:

Inorganic mineral powders make up the glass magnesium fireproof sanding board, making it mildew-resistant, fungus-resistant, insect-resistant, and termite-resistant, meeting European and American building material mildew-resistant standards

.

.

.

.