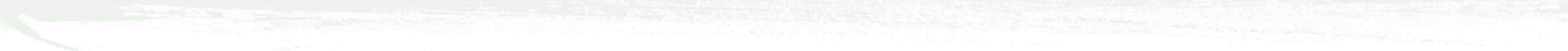

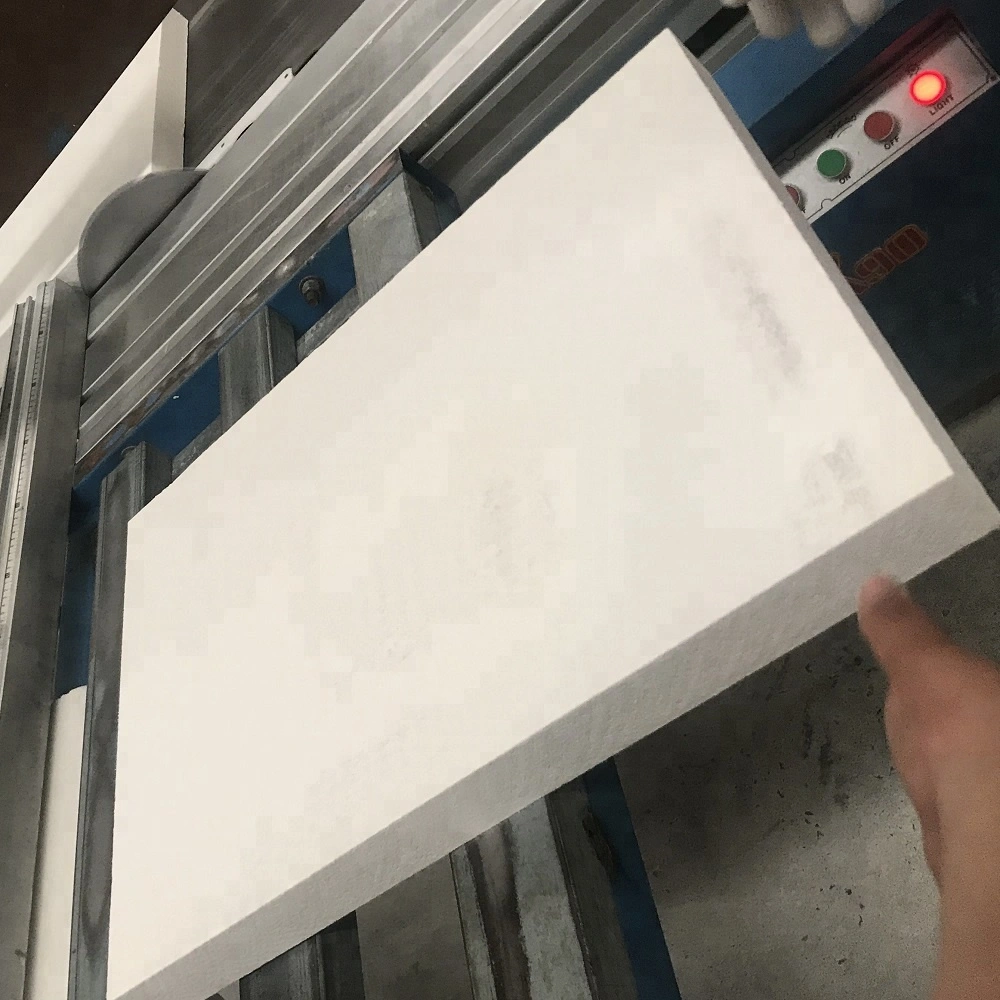

Magnesium Oxide Board (MgO Board) is made of fireproof materials. It is manufactured with proprietary compounds including MgO, MgCl₂, perlite, glass fiber, and chip compounds, delivering a versatile, multifunctional, non-combustible, and unique board.

This integrated, hard, inert, and paper-free building panel boasts superior properties compared to panels made of gypsum, clay, wood, or paper particles, enabling easier, better, and faster construction work.

MgO Board is ideal for both interior and exterior structures. It offers fire resistance for over 3 hours, has no sweating or corrosion issues, and is particularly suitable for use with steel frames. As a partition wall panel, it features high waterproofness to protect steel from oxidation.

MgO Board is nearly impermeable to fire, water, and insects; it does not support mold or mildew growth. It is non-toxic, non-flammable, and incombustible, with long-lasting durability and dimensional stability.

-

Fire Resistance

Magnesium oxide boards are made of Class A non-combustible materials tested by national authoritative institutions, with a fire resistance rating of up to 4 hours. They do not release harmful fumes when exposed to fire, ensuring personnel safety.

-

Moisture Resistance

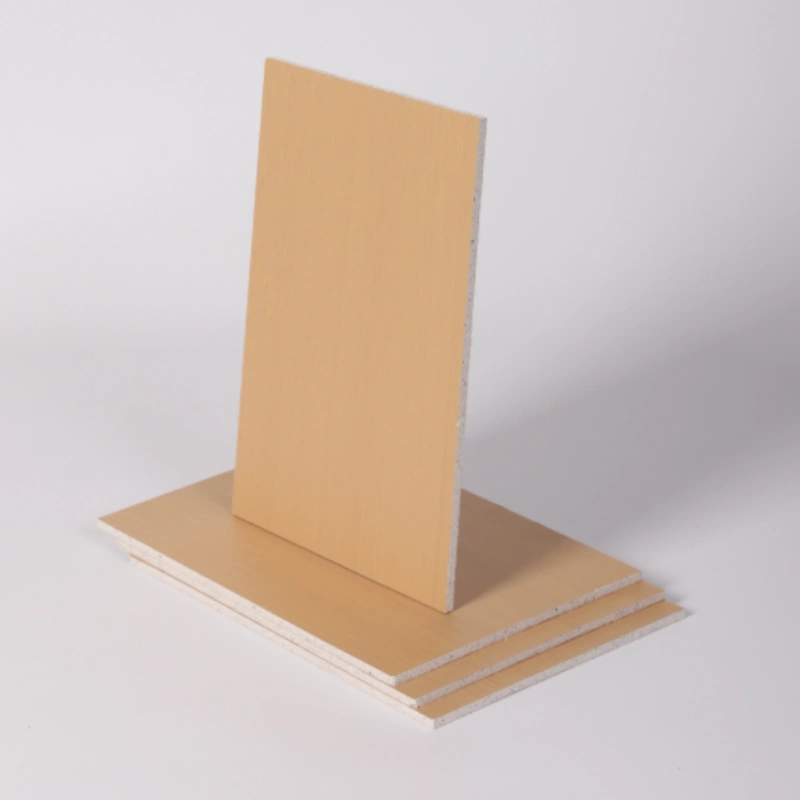

These boards have excellent moisture resistance. They can remain structurally intact without swelling or deformation even after being immersed in water.

-

Sound Insulation

They offer remarkable sound insulation performance, equivalent to a 95mm-thick soundproof wall or a 12mm-thick gypsum board, and comparable to a 150mm-thick ordinary solid brick wall.

-

Thermal Insulation

With a thermal resistance value of 1.14 ㎡·K/W, they exhibit outstanding thermal insulation performance.

-

Lightweight yet High-Strength

Easy to carry and cut, these boards facilitate convenient construction and effectively reduce costs. They maintain high flexural strength even at relatively thin thicknesses and can undergo various processing treatments.