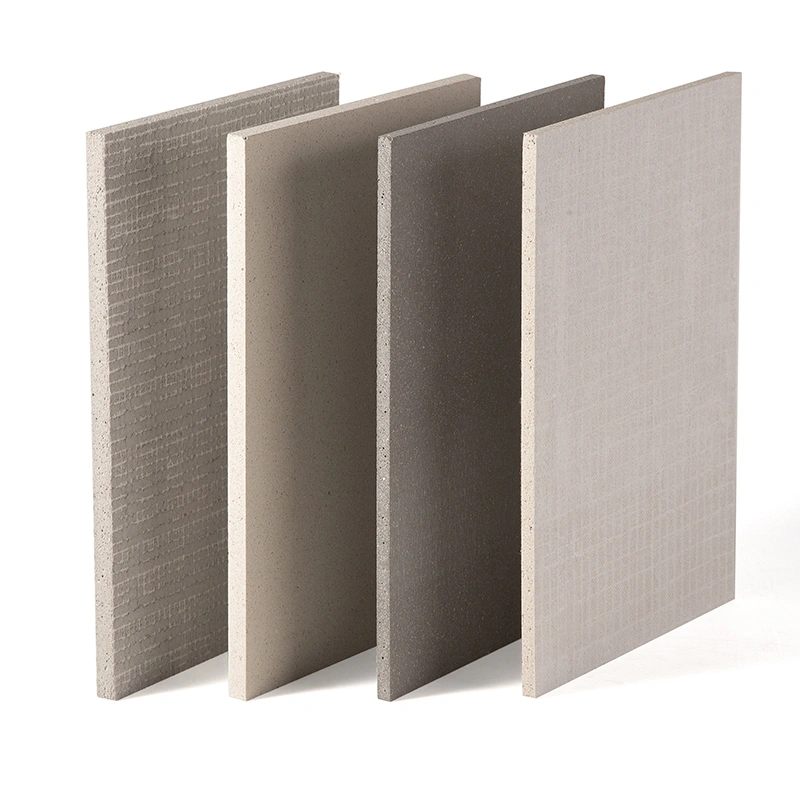

Product Features

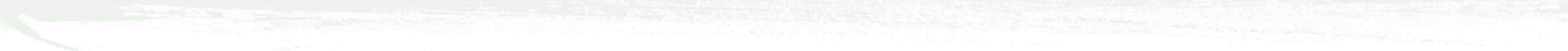

1. Long-Lasting Durability

Manufactured from cement, silica sand, and reinforced fibers, the board is highly resistant to weathering and environmental stress. It remains stable under prolonged exposure to sunlight, moisture, and temperature fluctuations, ensuring a long service life without rot, warping, or deformation.

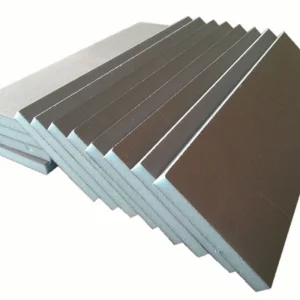

2. Excellent Fire Resistance (A1 Non-Combustible)

With an A1 fireproof rating, the board does not ignite or release toxic fumes when exposed to high temperatures. This significantly enhances building safety and makes it suitable for projects requiring strict fire protection standards.

3.High Structural Strength & Impact Resistance

Thanks to its dense composition and fiber reinforcement, the board offers excellent impact resistance and dimensional stability. It withstands daily wear and tear in high-traffic commercial spaces and provides dependable support for wall and ceiling systems.

4.Low Maintenance Requirements

Fiber cement board requires minimal upkeep. It does not rust like metal or require frequent painting and sealing like wood. Simple cleaning is sufficient to keep the surface in good condition.

Applications

-

Exterior Walls & Facades

-

Wall cladding for residential and commercial buildings

-

Curtain wall panels for high-rise buildings

-

Decorative walls for parks, landmarks, and municipal buildings

-

Interior Walls & Partitions

-

Office and commercial space partitions

-

Residential interior walls

-

Ceiling and suspended ceiling systems

-

Fireproof & Moisture-Resistant Areas

-

Kitchen and bathroom walls

-

Fire-rated walls in industrial buildings

-

Basement walls and damp environments

-

Roofing & Flooring Substrates

-

Special Industrial Applications

-

Factory walls and ceilings

-

Equipment soundproof enclosures

-

Cold storage and refrigeration walls