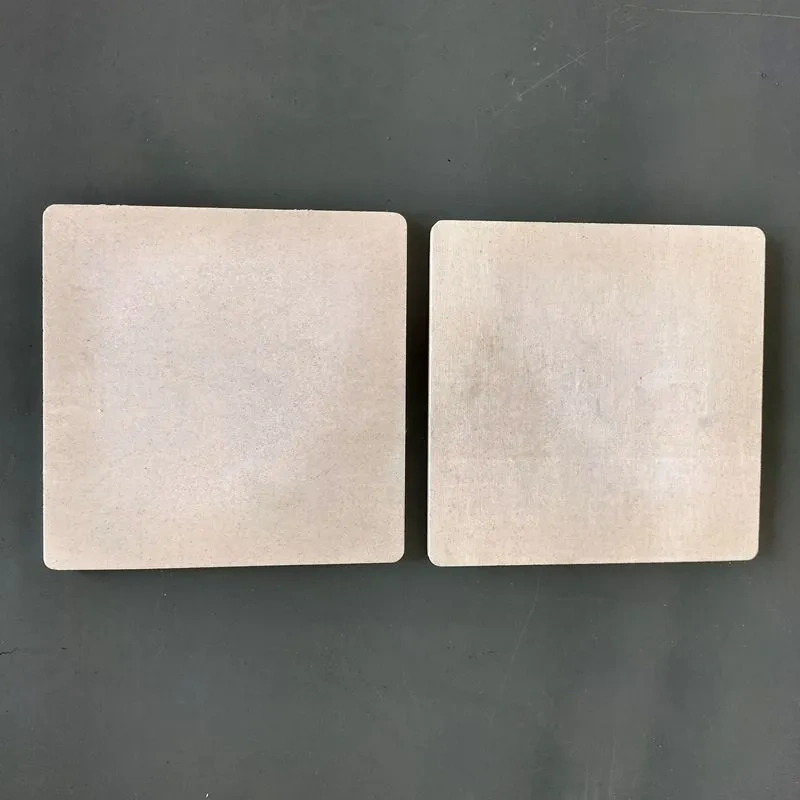

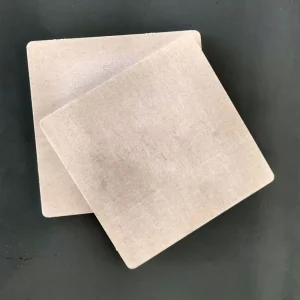

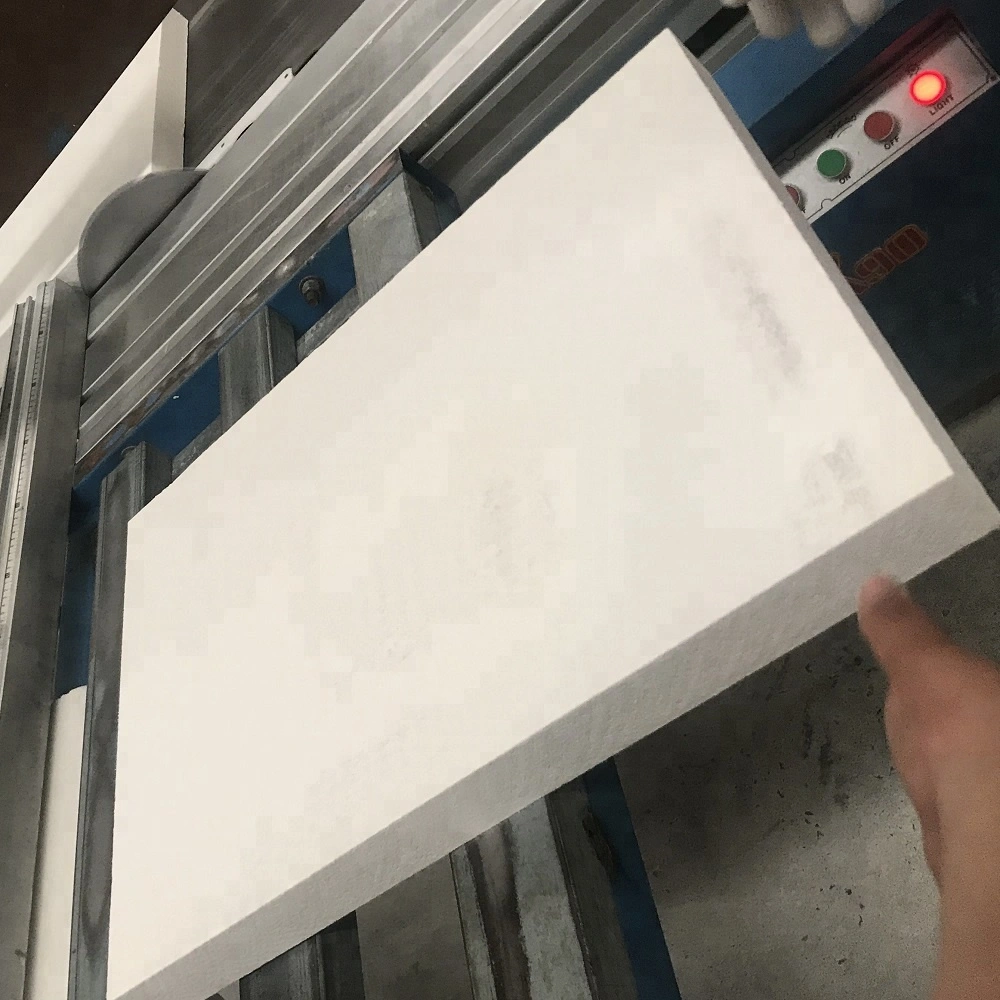

Glass magnesium sanded board is a new building material that is increasingly used. Why is this?

1. Abundant Raw Materials:

As a major magnesium resource country, China possesses abundant magnesium oxide resources, particularly magnesium chloride, which has the largest resources and the widest range of applications. The development of magnesium chloride products spans over 80 years, with many setbacks along the way.

2. Greater Attention:

In recent years, the research and development of magnesium oxychloride products has received significant attention in developed countries such as Europe, the United States, and Japan. These countries have established research institutes and industry organizations to conduct research on magnesium oxychloride products. Magnesium oxychloride products are also widely used in developed countries and regions, as well as in Asia, the Middle East, and Russia.

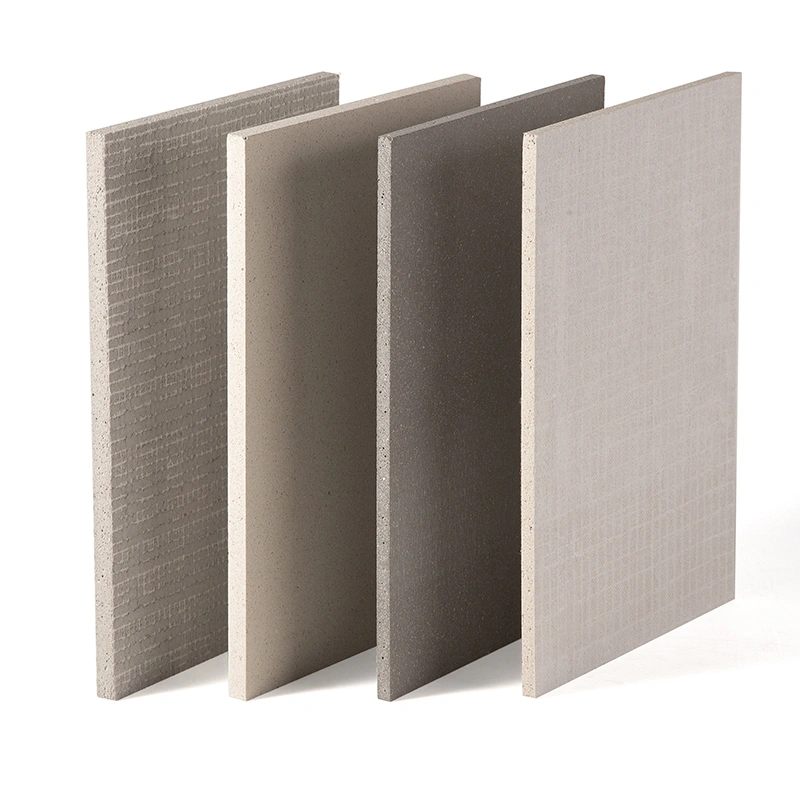

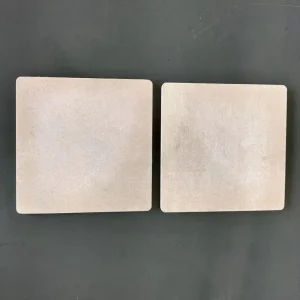

Aluminum silicate board: A chemical material composed of magnesium oxide, magnesium chloride, water, and filler (plant fiber) in a specific ratio.

3 Clear Advantages:

Features: Lightweight, high strength, waterproof, fireproof, mildew-resistant, heat-insulating, and formaldehyde-free.

Applications: Commonly used in container homes, Qinggang villas, and prefabricated homes, and processed into furniture.