Key Features

-

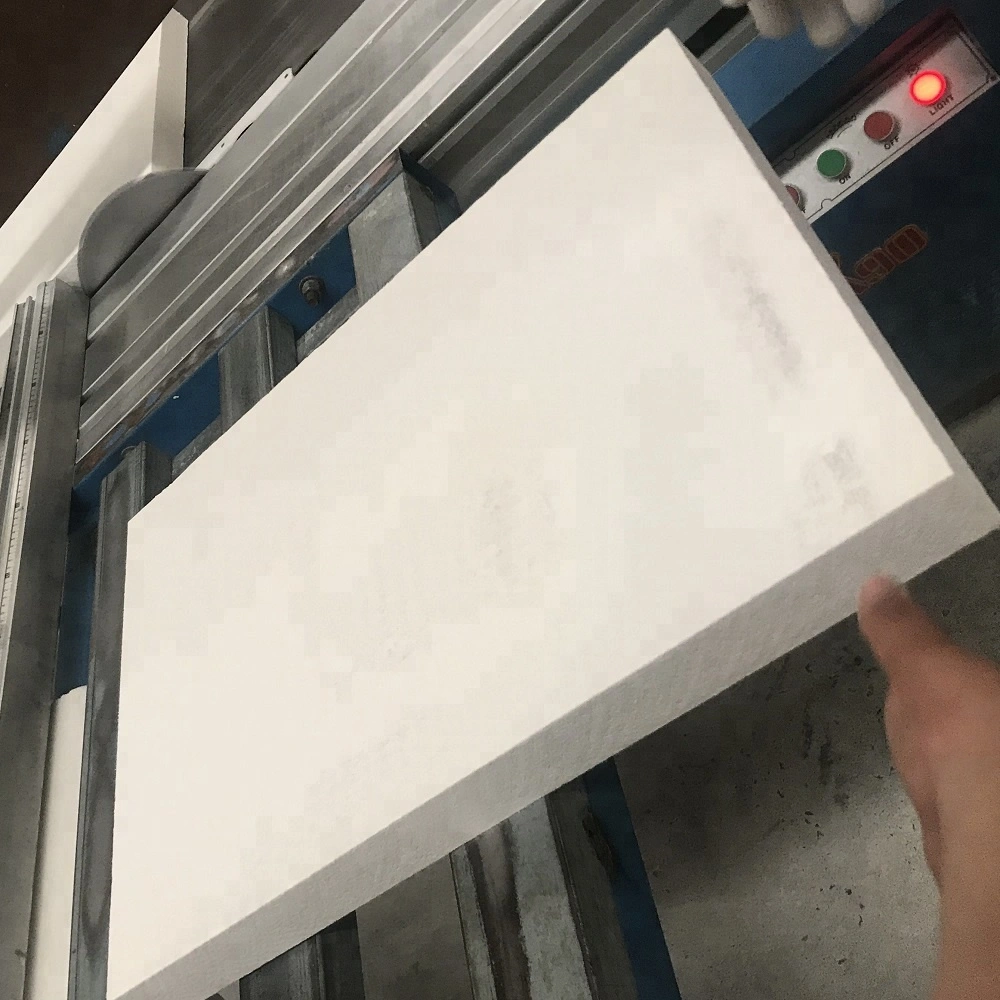

Low Bulk Density: As a furnace lining material, ceramic fiber blankets enable lightweight and efficient heating furnaces, significantly reducing the load on steel structures and extending their service life.

-

Low Specific Heat: The low specific heat of ceramic fiber blankets reduces energy consumption during kiln temperature adjustments, making them especially advantageous for intermittent heating furnaces.

-

Low Thermal Conductivity: Ceramic fiber blankets maintain low thermal conductivity even at high temperatures, providing excellent insulation performance.

-

Thermochemical Stability: Ceramic fiber blankets remain structurally stable under sudden temperature changes. They do not delaminate at high temperatures and resist bending, twisting, and mechanical vibrations, ensuring reliable performance under thermal shock conditions.

-

High Thermal Responsiveness: The high thermal responsiveness of ceramic fiber blankets makes them well-suited for automated industrial furnace control systems.

-

Sound Insulation: Ceramic fiber blankets are widely used in the construction industry for thermal and acoustic insulation and are also applied in high-noise industrial furnaces to improve workplace and living environment quality.

Applications of Ceramic Fiber Blanket

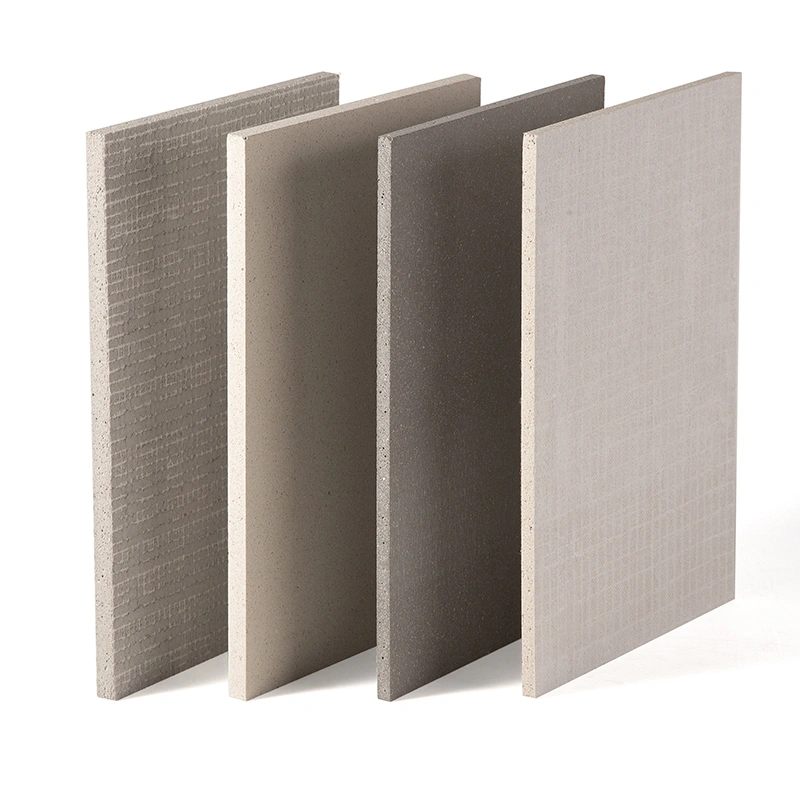

1. Industrial Furnaces and High-Temperature Equipment

Ceramic fiber blankets are commonly used as lining materials in high-temperature furnaces and heat treatment equipment in steel, glass, and ceramics industries. Their high-temperature resistance minimizes heat loss and significantly improves operational efficiency.

2. Refractory and Thermal Insulation

Used in both industrial and construction settings, ceramic fiber blankets act as effective fireproof and thermal insulation materials. They are particularly suitable for areas around walls, doors, and windows, preventing the spread of flames and enhancing safety.

3. Automotive Industry

In automotive applications, ceramic fiber blankets provide thermal insulation and noise reduction in exhaust systems and mufflers. They withstand high-temperature conditions, reduce heat loss, and minimize noise pollution.

4. Power Equipment

Ceramic fiber blankets are applied in boilers and heat exchangers in power plants to reduce heat loss and improve overall equipment efficiency.

5. Chemical Industry

In petrochemical and chemical processing, ceramic fiber blankets serve as insulation for pipes, reactors, and heating devices. They are resistant to high temperatures and corrosive environments, ensuring reliable performance.

6. Aerospace Applications

Used in aircraft and spacecraft thermal protection systems, ceramic fiber blankets provide excellent insulation under extreme temperatures, safeguarding equipment from thermal damage.

7. Household Appliances

Ceramic fiber blankets are employed as internal insulation layers in ovens, microwaves, and water heaters, improving thermal efficiency and minimizing energy loss.