Product Description

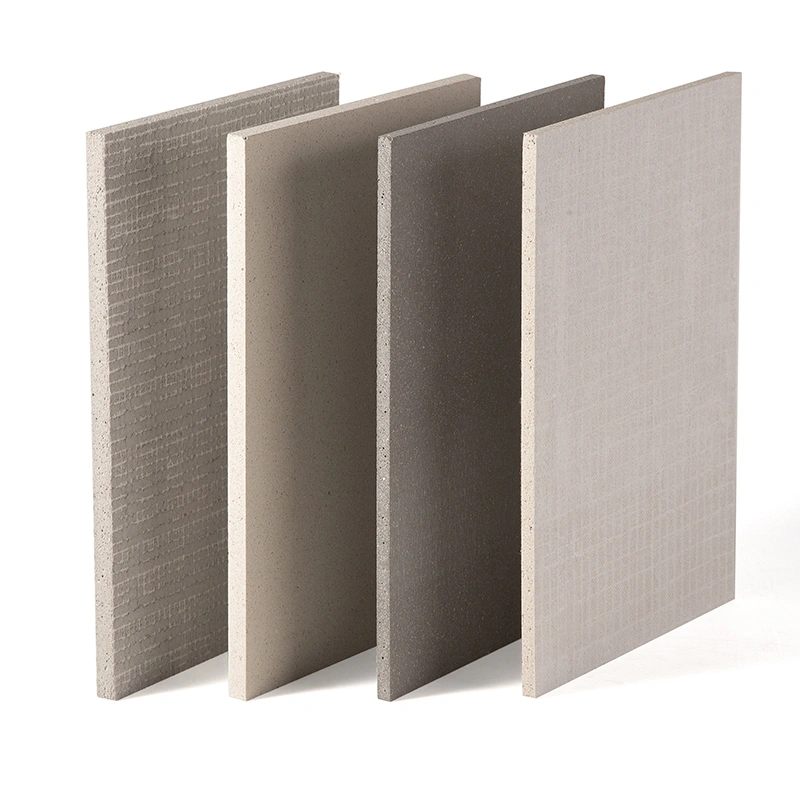

Aluminum Silicate Board is a lightweight, high-performance refractory material manufactured from premium alumina–silica fibers. Engineered for thermal applications that require exceptional rigidity and stability, the board is designed to withstand continuous service temperatures up to 1430°C. Its enhanced density gives it superior insulation efficiency, excellent resistance to wear, and improved durability under demanding operating conditions.

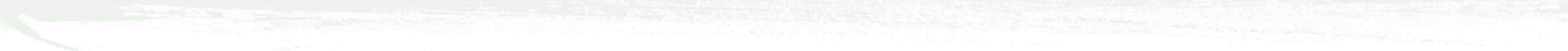

Produced through a precision vacuum-forming process, the board offers significantly higher structural strength and better resistance to high gas velocities compared with traditional ceramic fiber blankets. This makes it an ideal choice for furnace linings, boiler walls, duct insulation, chimney systems, and other high-temperature industrial environments.

Thanks to its low thermal conductivity and low heat storage, it helps reduce energy consumption, shortens furnace cycle times, and enables faster access for maintenance. These performance advantages make it a reliable, long-lasting insulation solution for modern industrial furnaces and heat-processing equipment.

Key Advantages

-

Excellent Fire Resistance

-

Achieves A1 non-combustible standard

-

Does not release toxic smoke during fire, ensuring building safety

-

High-Temperature Insulation

-

Lightweight and Easy to Install

-

Lightweight structure reduces construction load

-

Easy to cut, drill, and fix, saving installation time

-

Moisture and Corrosion Resistant

-

Resistant to humidity, mold, and chemical corrosion

-

Maintains performance in harsh environments

Why Choose Us

1. Customization Support

As an original manufacturer, we offer fully customizable solutions based on your samples. We can tailor the board to your required dimensions and temperature ratings to meet your specific needs.

2. High Performance

Our aluminum silicate boards feature excellent thermal insulation, sound absorption, electrical insulation, and fire resistance, ensuring reliable performance in demanding applications.

3. Wide Range of Applications

Suitable for multiple industries including steel, non-ferrous metals, ceramics, and petrochemicals, our boards provide versatile solutions for industrial and construction needs.