Product Description

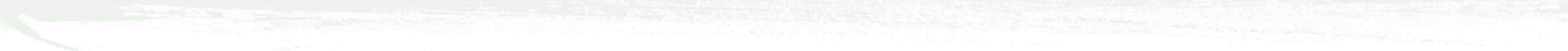

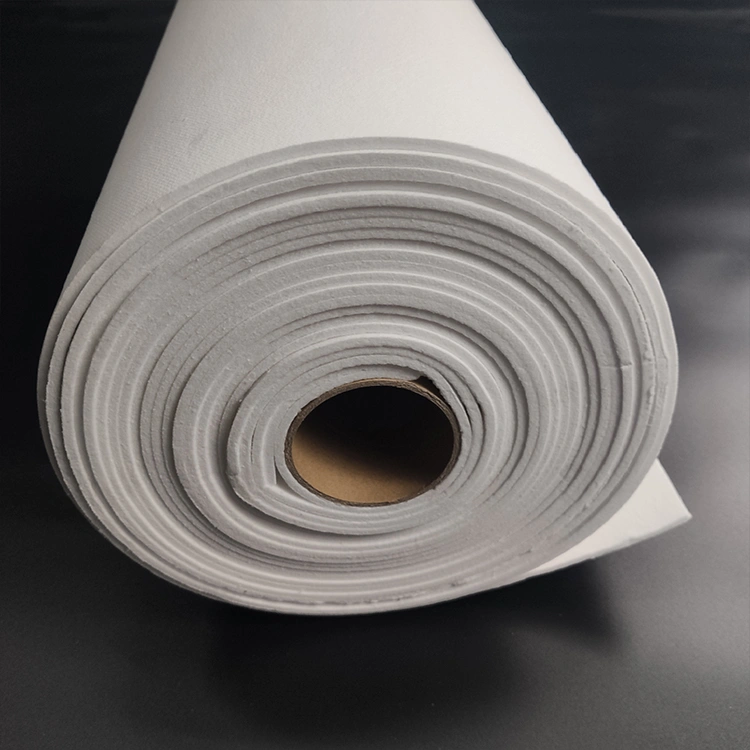

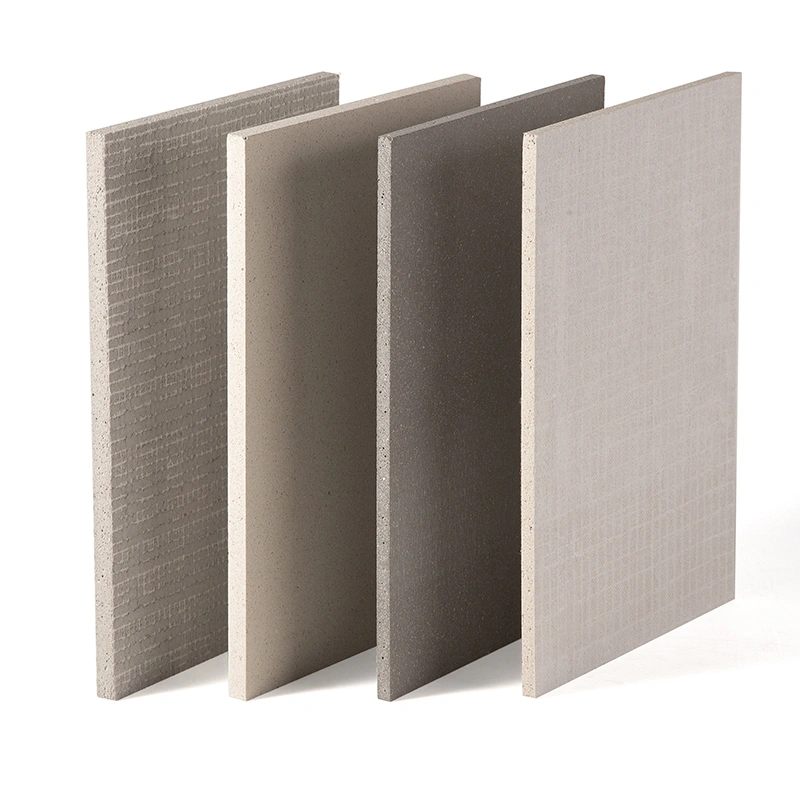

The aluminum silicate blanket is a high-performance insulation material made from high-purity aluminum silicate fibers. Engineered for extreme high-temperature environments, this blanket is lightweight, flexible, and durable, providing superior thermal resistance and low thermal conductivity. Its excellent dimensional stability ensures minimal shrinkage and deformation even under prolonged exposure to temperatures up to 1260–1430°C (2300–2600°F).

Manufactured using advanced fiber processing technology, the aluminum silicate blanket offers exceptional chemical stability, corrosion resistance, and fireproof performance. It maintains its insulating properties in harsh industrial conditions, making it a reliable and long-lasting solution for high-temperature insulation needs.

With its combination of thermal efficiency, mechanical strength, and ease of installation, the aluminum silicate blanket is ideal for use in demanding industrial, commercial, and technical applications.

Key Features

-

Low Bulk Density: As a furnace lining material, ceramic fiber blankets enable lightweight and efficient heating furnaces, significantly reducing the load on steel structures and extending their service life.

-

Low Specific Heat: The low specific heat of ceramic fiber blankets reduces energy consumption during kiln temperature adjustments, making them especially advantageous for intermittent heating furnaces.

-

Low Thermal Conductivity: Ceramic fiber blankets maintain low thermal conductivity even at high temperatures, providing excellent insulation performance.

-

Thermochemical Stability: Ceramic fiber blankets remain structurally stable under sudden temperature changes. They do not delaminate at high temperatures and resist bending, twisting, and mechanical vibrations, ensuring reliable performance under thermal shock conditions.

-

High Thermal Responsiveness: The high thermal responsiveness of ceramic fiber blankets makes them well-suited for automated industrial furnace control systems.

-

Sound Insulation: Ceramic fiber blankets are widely used in the construction industry for thermal and acoustic insulation and are also applied in high-noise industrial furnaces to improve workplace and living environment quality.