Product Description

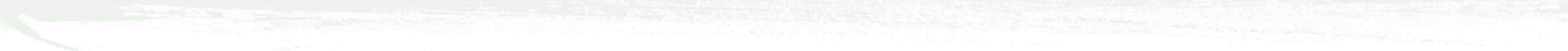

Fiber cement board is a high-quality building material made from cement, cellulose fibers, and mineral aggregates. It is completely asbestos-free and manufactured through advanced high-pressure and autoclave curing processes, ensuring exceptional strength, stability, and long-term durability.

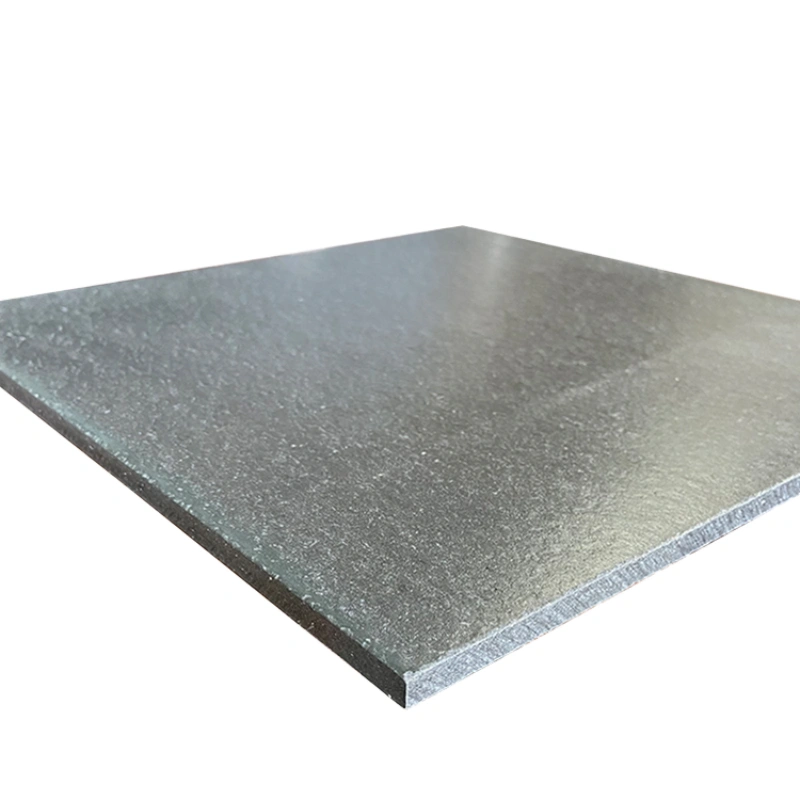

Designed for both interior and exterior use, the board is available in various thicknesses and can be applied to walls, ceilings, and flooring substrates. Its non-combustible properties make it a reliable option for projects requiring fire-safe and moisture-resistant performance.

Easy to cut, install, and finish, fiber cement board can be painted, laminated, or combined with decorative surfaces such as wood veneer or metal. With its versatility and superior durability, it is an ideal material for residential, commercial, and industrial construction projects.

Key Features

1. Durable and Long-Lasting

Manufactured with a high-density formulation, the board offers strong impact resistance and excellent structural stability. It is designed for long-term use in residential and commercial applications.

2. Non-Combustible Fire Protection

Classified as an A1 non-combustible material, fiber cement board does not ignite or release harmful gases under high temperatures, supporting safer building performance in fire-rated systems.

3. Water- and Moisture-Resistant

With a low water absorption rate, the board performs well in humid environments such as bathrooms, kitchens, and exterior facades. It does not warp, swell, or support mold growth.

4. Safe and Environmentally Friendly

Made without asbestos or formaldehyde and compliant with international green building material standards. Installation is clean and low-odor, contributing to a healthier indoor environment.

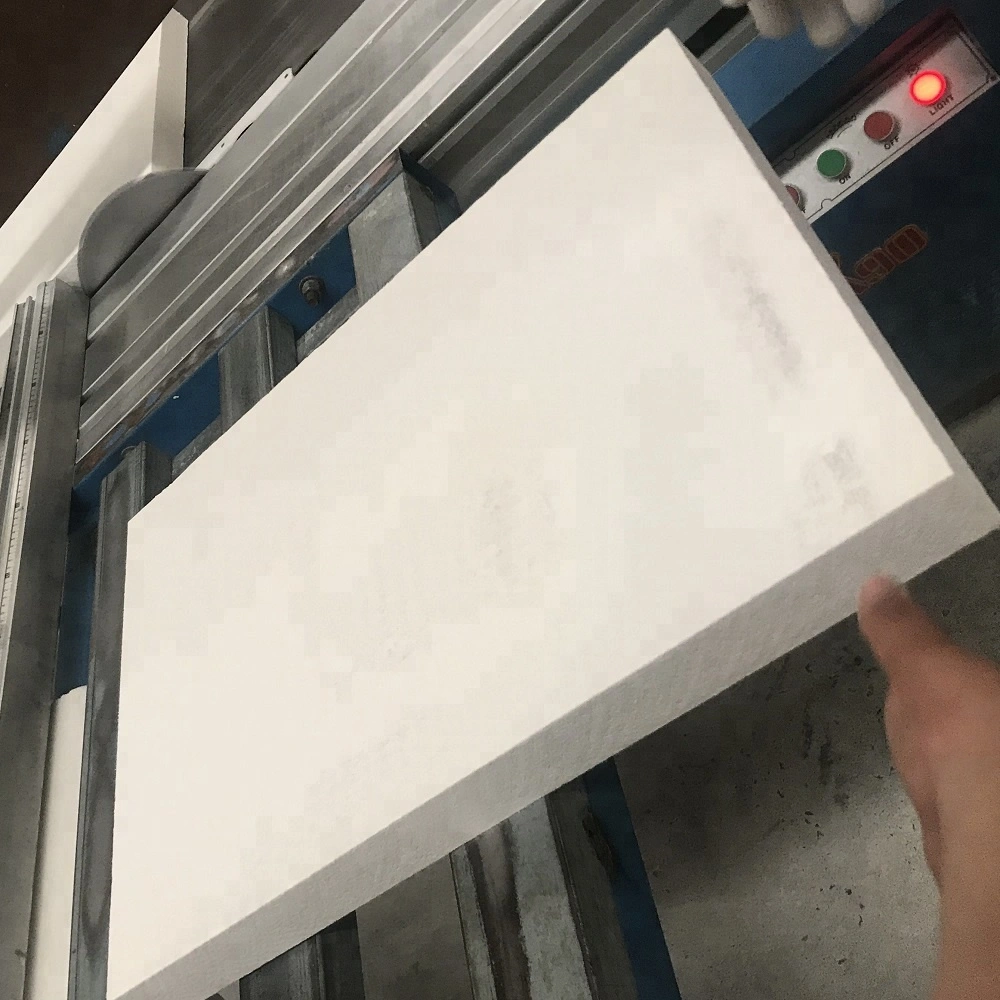

5. Easy Installation

Lightweight and simple to cut, the board supports dry construction methods. This helps reduce installation time and labor requirements on-site.

6. Thermal and Acoustic Performance

The low thermal conductivity helps improve energy efficiency, while the dense structure provides effective sound insulation for enhanced indoor comfort.

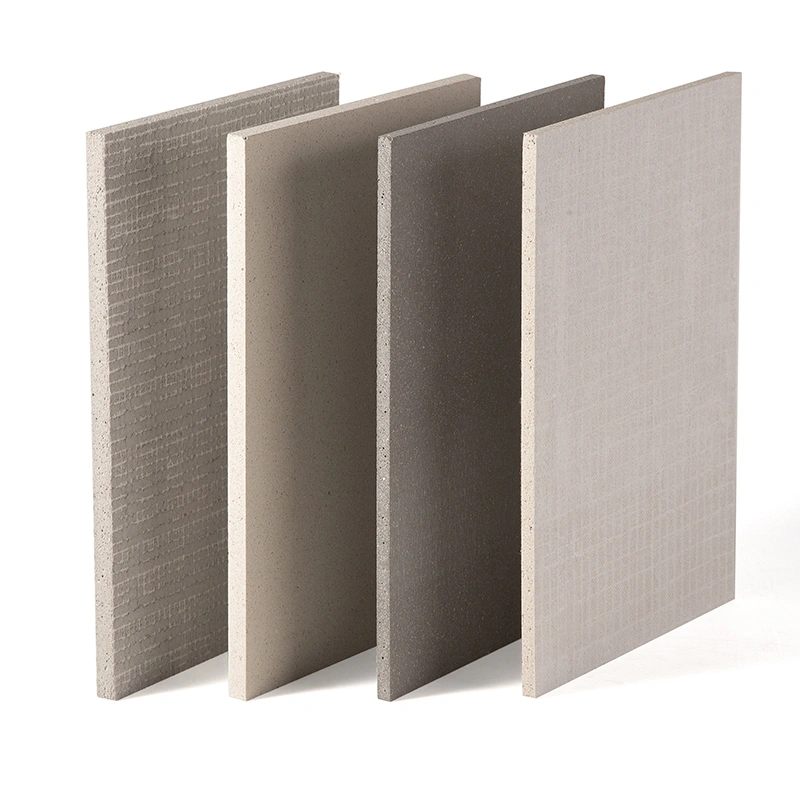

7. Versatile Aesthetic Options

Available in a variety of finishes such as wood grain, stone texture, and solid colors. These options support modern architectural styles and creative design requirements.

8. Wide Application Range

Suitable for exterior cladding, interior partition walls, ceilings, flooring substrates, wet areas, and other residential or commercial construction scenarios.