Specifications

| Item |

Value |

| Place of Origin |

Shandong, China |

| Chemical Composition |

Aluminum Silicate |

| Tensile Strength (≥ MPa) |

0.5 |

| Fiber Diameter |

3.5 μm |

| Thermal Conductivity (W/m·K) |

0.08 – 0.16 |

| Application |

Thermal Insulation |

| Thickness |

20 – 150 mm (customizable) |

| Width |

400 – 600 mm (customizable) |

| Length |

600 – 1000 mm (customizable) |

| Grade |

A1 (Non-combustible) |

| Working Temperature |

400 – 1800 °C |

| Linear Shrinkage (1800°F, 3h) |

1.1% at approx. 1100°C |

Key Features

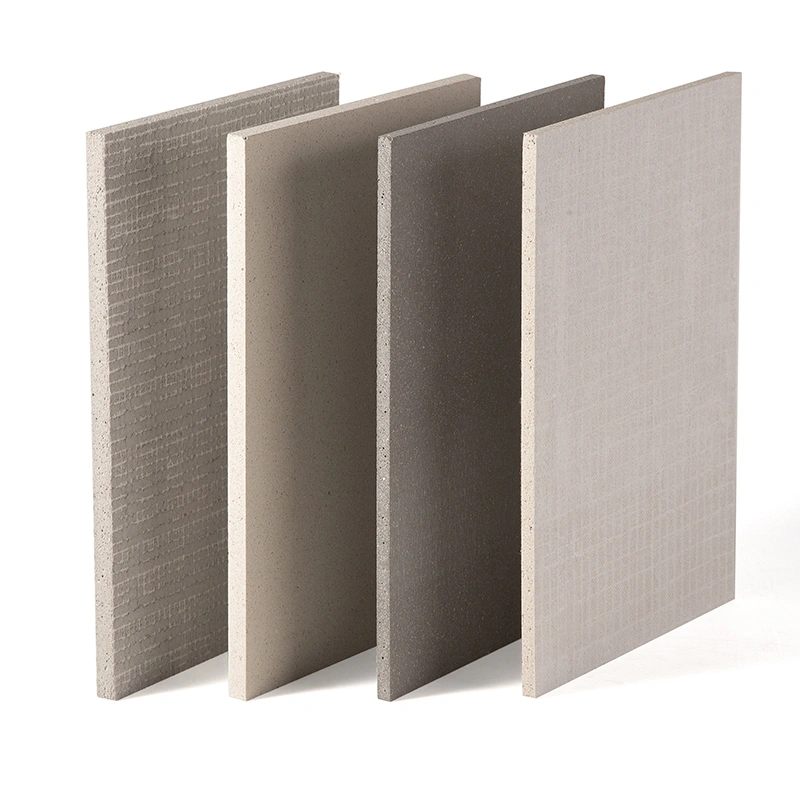

1. Premium Thermal Insulation Performance

Manufactured from high-quality aluminum silicate ceramic fiber and polycrystalline mullite materials, this insulation board delivers outstanding resistance to heat and long-term durability. Its stable composition ensures reliable performance even in demanding thermal environments.

2. Versatile for Multiple High-Temperature Applications

Designed to meet a wide range of refractory and insulation requirements, the board is available in various customizable dimensions. It is well-suited for furnaces, kilns, industrial equipment, and other applications where consistent thermal protection is essential.

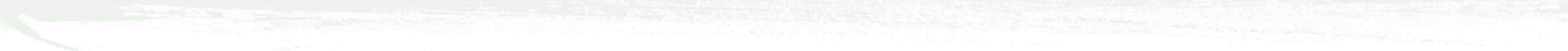

3. Strong and Stable Structural Design

With available thicknesses from 20–150 mm, widths from 400–600 mm, and lengths from 600–1000 mm, the board provides excellent mechanical strength and dimensional stability. This robust construction enhances overall performance in both industrial and commercial settings.

4. Low Thermal Conductivity for Efficient Insulation

Engineered to reduce heat transfer effectively, the ceramic fiber board features a low thermal conductivity range of 0.08–0.16 W/m·K. This makes it an ideal choice for refractory furnaces, industrial kilns, and high-temperature insulation systems requiring energy efficiency and reliable heat containment.

5. Environmentally Friendly & Energy Efficient

This product serves as an eco-friendly alternative to traditional insulation materials. It contributes to reduced energy consumption, improved thermal efficiency, and lower operational costs—making it both a sustainable and cost-effective solution.