| Item name |

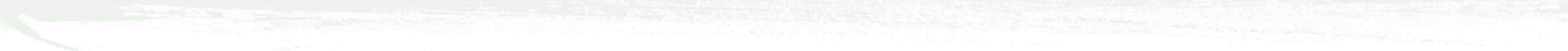

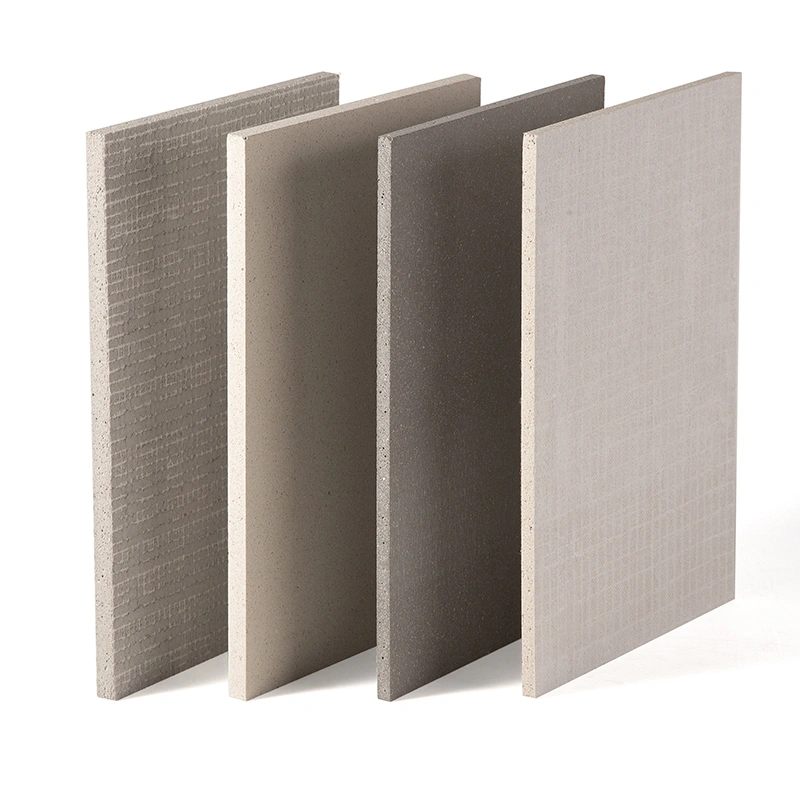

Magnesium oxide board fireproof sanding Mgo board |

| Size |

1220*2440mm, 1220*3050mm,special size should speically design |

| Thickness |

3mm -50mm |

| Color |

White; Pink; Purple; Green; Grey; Blue; Black; Brown, or customized |

| Edge |

Square; tapered ; T&G; L - ship lap, Tongue &Groove, Beveled or customized |

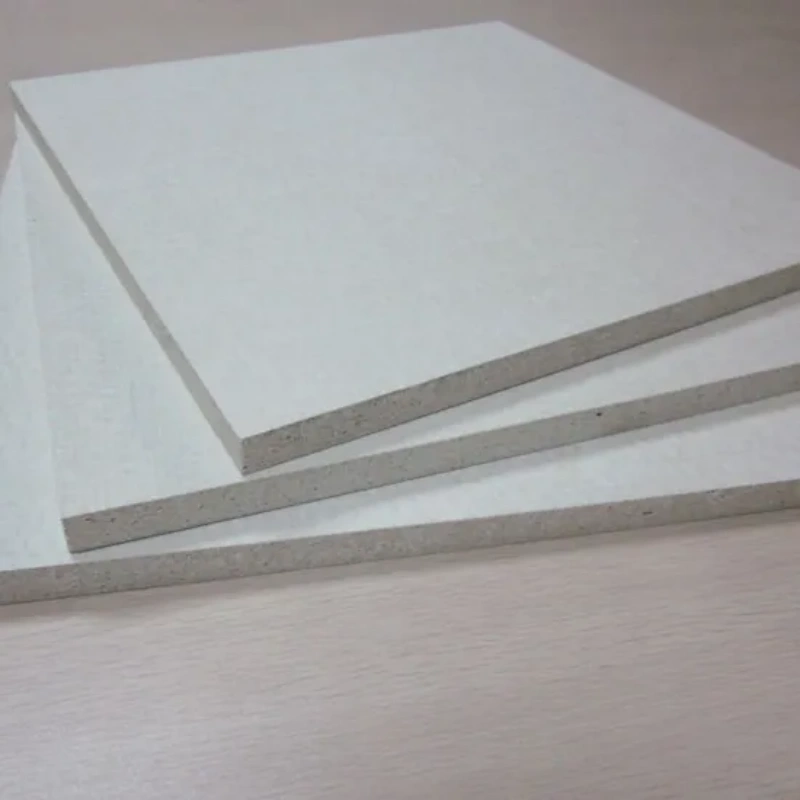

| Capacity |

3000 pcs/day |

| Moisture content |

≤ 10% |

| Dry Shrinkage |

≤0.12% |

| Moisture expansion |

≤ 0.15% |

| Flexural strength |

19~25MPa |

| Screw holding strength |

22.7N/mm |

| Water absorption |

≤13.3% |

| Density |

1.5g/cm3,or based on your requirement |

| Fire proof rate |

Class A |

| Raw Material |

1-Class A MGO powder, Content of Magnesium≥ 85% , Activity≥60%

2-Class A MgSo4 : Purity:99% , Activity ≥ 65%

3-Filling Material: Bamboo & saw dust (water content within 10%), bamboo is low water absorption, won't easy to cause mold problem.

4-Closed-cell pearlite (low water absorption) . |

(Fireproofing Fiber Cement Panel Making Machine, Sulphate & Chloride Free)

Equipped with PLC automatic control for centralized part management, enabling high automation, reduced labor input and enhanced efficiency. Features a dedicated automatic feeding system for precise measurement and speed control.

Adopts PLC intelligent control to realize full automation of heating, heat mixing, regulation and maintenance processes.

PLC-based automatic control with centralized part management; integrates plate-mold re-separation function to prevent adhesion. Ensures high automation, low labor demand and high efficiency.

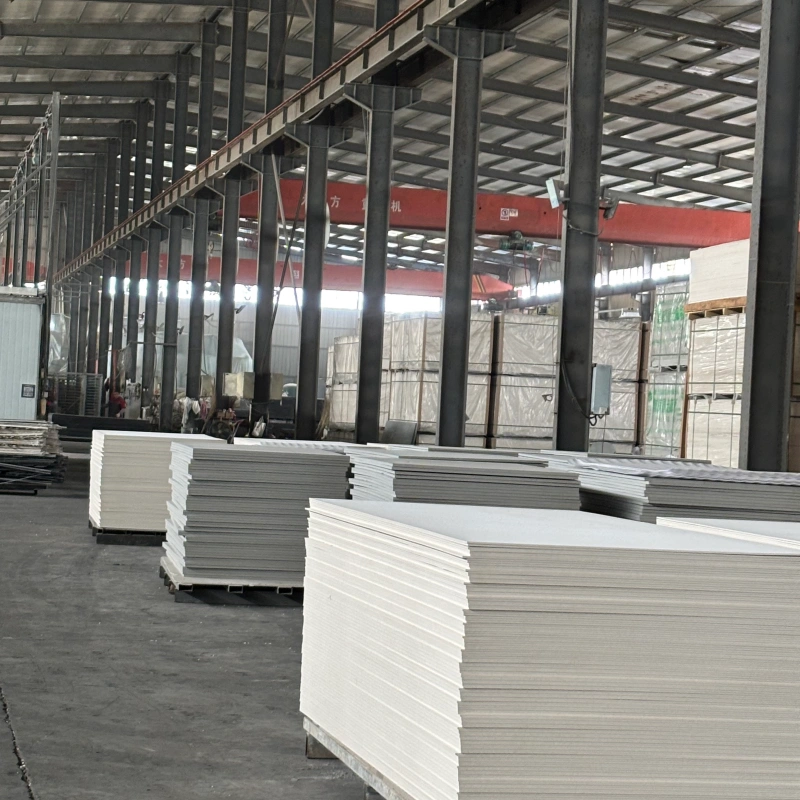

PLC-controlled entire line with integrated functions: automatic loading, sorting, cutting, stacking and edge material feeding. All processes are closely linked, achieving high automation.

Configured with two or more linked sanding machines and automatic plate turnover function, meeting various customer sanding requirements and quality standards.